Risk Evaluation - Gas Distribution Lines in Sewers

Risk Evaluation White Paper :

Creating High Confidence Results for Cross Bore Elimination Projects

Inspection programs that do not have the high confidence verification processes are suspect and provide little or no value and may be worse than no inspections at all. The result can be a belief that lines have been cleared of cross bores, when they may not have been. Implementation of a cross bore elimination program must include verification and auditing processes that all lines in a defined area have been inspected to the extent appropriate and cost effective.

suspect and provide little or no value and may be worse than no inspections at all. The result can be a belief that lines have been cleared of cross bores, when they may not have been. Implementation of a cross bore elimination program must include verification and auditing processes that all lines in a defined area have been inspected to the extent appropriate and cost effective.

This paper illustrates methodology to analyze processes which compare cost effectiveness versus high confidence.

Published December, 2011

______________________________________________

What are some of the Considerations that are important to Evaluating Risk of Gas Lines in Sewers?

Physical installation and inspection elimination processes issues:

click here to see Type 1 Cross Bore

- Trenchless installation of gas lines

- Trenchless includes, percussion moles, horizontal directional drills and plows

- Do not allow installer to "see" location of work.

- High risk of cross bores results.

- Proximity of gas lines to sewers

- Gas lines are frequently laid more shallow in traditional construction but with trenchless tools can more easily installed deep.

- Sanitary sewers are often the lowest elevation utility

- Elevation

- Water table - may result in shallow sewers

- Rock soil conditions - may result in shallow sewers

- Basements - often result in deeper sewers

- Slab or mobile home construction - may allow shallow sewers

- Deep gas main - allows for deeper gas laterals

- Allow adequate for tolerance for depth locating accuracy

- Allow for depth readings to be affected by surface excavation or filling. Recording elevations of surface and depth may be better for long term records than depth alone.

- Horizontal proximity

- Additions to original structure - more than one lateral connection more likely.

- Lax sewer regulations or lax enforcement of sewer regulations allowing "illegal" or non typical installations.

- Yard drains to sanitary sewer line

- Gutter drains to sanitary sewer line

- Sanitary sewer connection from structure to Storm sewer

- Storm sewers may need to be inspected

- Known locations of gas and sewer may be at safe distances.

- Septic tank systems may be connected to the rear of the structure vs. gas lines at front. Danger is that positions must be known, not inferred.

- Laterals may exit from front, side or rear of structure.

- Laterals may have wyes or tees connecting to same structure, other structure, gutters or yard drains.

- Sewer tap connection to mainline may wye to multiple structures and drains.

- As built drawings are often unreliable as to position of utility.

- As built drawings do not reflect all installations.

- Allow adequate tolerance for equipment locating accuracy.

- Pressure class of gas line - higher pressure increases risk if larger explosion or fire - and potential to affect multiple structures. May justify priority.

- Multiple family structures - higher risk of damage and injury

- Apartments

- Duplexes - multiple sewer lateral potential is higher

- May justify priority.

- High occupancy structures

- Schools

- Hospital

- Nursing homes

- Office buildings

- Sports event structures

- May justify priority.

Note: Cross bores of gas lines in sewers have been identified at schools and hospitals by CCTV inspections.

- Reports of cross bores based upon utility information or incidental drain cleaner or contractor reports.

- There has not a known tracking system that has been demonstrated effective at incorporating all such incidents. Under reporting may be expected.

- Proactive risk reduction is greatly emphasized.

- Explosions and fires that resulted from a cross bore

- Historically preventive actions have dramatically increased as a result of an explosion.

- Any cross bore explosions may justify an inspection program.

- Proactive risk reduction is greatly emphasized.

Additional Risk Considerations of Explosion from a Cross Bore

- Fiber optic and communications cables can be drilled through sewers then into a gas line. or in the reverse.

- Pressurized gas can flow along the new construction bore path from the intersected gas line into the sewer and continue into the structure - explosion or fire can result as if the gas line was directly in the sewer.

- Would expected to be a more immediate risk than of a latent gas line in a sewer.

Click here to see Class 2 Cross Bore

Risk Review

- Risk avoidance objectives, economic feasibility and effectiveness of a cross bore elimination project should reflect uniqueness of the service area Cookie cutter approach may not be efficient or effective in all cases.

- High priority risks should be determined early and selected first.

- Documented and thorough processes and techniques are required for an effective program.

- Processes that do not have repeatable and verifiable results should not be selected.

- QA/QC processes need be required to ensure that the selected processes and work result in high confidence results.

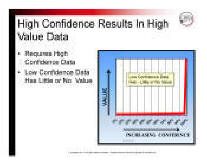

- Very high confidence results have value. See Table above.

- Low quality results have little or no value and may lead to an over confidence.

- Low confidence processes, work, tools and procedures can leave a false impression that inspected areas are cross bore free and require rework later.

- GPS combined with resulting GIS mapping systems allow for accountability and a level of verification of work performed that should be strongly considered.

Multiplying the Results for Best Bang for the Buck

- Store data in a manner that it is secure and readily retrievable.

- Cross bore elimination projects have lost data or was not verifiable that required costly re-inspections.

- GIS systems allow easy sharing of the information

- Property owners and professional drain cleaners that have access to readily processes that do not have repeatable and verifiable results should not be selected. accessible data/mapping can help reduce risk from explosions.

- Drain cleaning tools can be selected to reduce risk in areas that are " Not Cleared".

- Drain cleaning in areas shown "Not Cleared" may request assistance from the gas distribution company.

- Utilities should select process suited for the area of service. One method may not be the most effective for all circumstances.

- Good records and accessibility are essential.

- Plan projects over realistic time to balance safety, availability of quality workmen, process development, QA/QC systems, GIS integration and economics.

- Rapid gear up may result in poor work, deterioration of confidence and resulting inefficient program

Share Successes - Communicating Best Practices. Share within the industry your effective processes.

- Home

- History

- News

-

Leading

Practices

-

Legacy Cross

Bores

-

New

Construction

-

System

Integrity

-

Risk Evaluation

-

Drain

Cleaner Safety

-

Videos/Websites

-

Photos-Cross Bores+

-

State

Locating Requirements

-

Papers

and Presentations

-

Tools and Technology

-

Information

Sources

-

Join Now -

Membership

-

Contact

Us

-

Events

-

Directors

-

Search